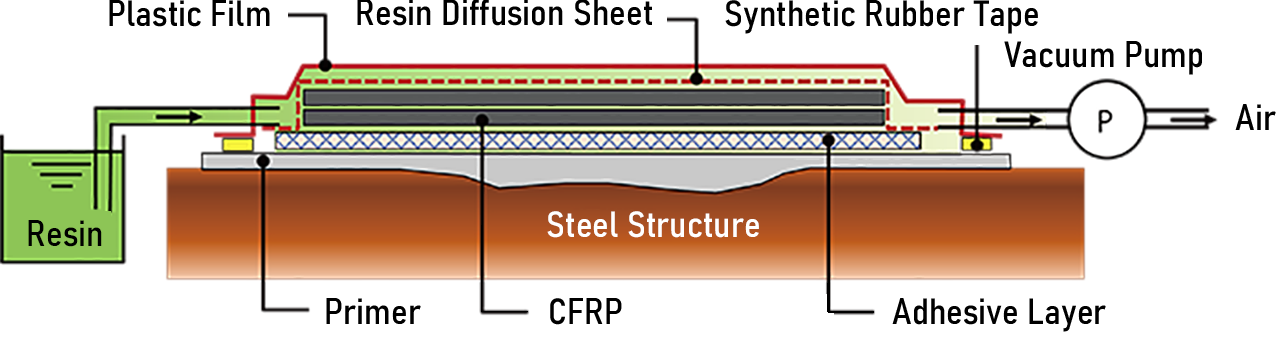

The Vacuum-assisted Resin Transfer Molding method (VaRTM), which is used in the manufacturing of FRP structural components for wind turbine blades and the aircraft field, is applied to the repair and reinforcement of steel structures.

This is a new repair and reinforcement technique that uses vacuum pressure to inject resin, enabling the easy molding of multiple layers of carbon fiber sheets and the rapid production of high-quality CFRP reinforcement materials. It can be used not only for repairing cross-sectional losses due to steel corrosion but also for reinforcing joints in steel structures.

※ The On-site VaRTM method is a patented technology developed by Toray Industries, Inc.

| Materials | Product Name | Specification |

|---|---|---|

| TORAYCA® Cloth | UM46-40P | UM46-40P Unidirectional CF sheet with particles, weight: 400g/m²Tensile Strength: 2400 MPa or higher, Tensile Modulus: 440 Gpa |

| Adhesive Layer Sheet | G-Flow | G-Flow GF Mesh Sheet, weight: 500g/m² |

| MC300A | MC300A Chopped Strand Mat, weight: 300g/m² |

|

| Impregnation Adhesive Resin | AUP40T1 | AUP40T1 Room temperature curing epoxy resin, low viscosity |

| Primer | E258R | E258R Room temperature curing epoxy resin, high viscosity (putty-like) |

※ TORAYCA® is a registered trademark of Toray Industries, Inc.

| Vacuum Pump | Digital Vacuum Gauge | Vacuum Can |

|---|---|---|

|

|

|

| Methods | Steel Plate Attachment | CF Sheet Bonding (Hand Lay-Up) |

On-Site VaRTM Method |

|---|---|---|---|

| Picture |  |

|

|

| Strong points |

|

|

|

| Weak points |

|

|

|

| Methods | On-Site VaRTM Method |

|---|---|

| Picture |  |

| Strong points |

|

| Weak points |

|