In recent years, road subsidence accidents have been occurring one after another throughout Japan. Many of these are attributed to damage to aging drainage pipes and the deterioration of underground structures. There are growing concerns that such accidents will increase in the future as buried infrastructure continues to deteriorate.

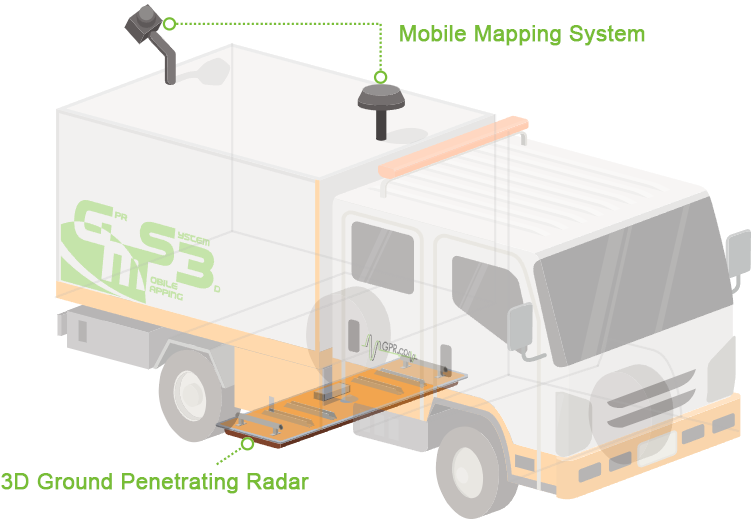

To address this serious issue, our company utilizes the "Subsurface Cavity Investigation Vehicle (GMS3)" equipped with a high performance ground penetrating radar. This system enables non-destructive and high-precision detection of cavities formed beneath roads, aiming to prevent subsidence accidents before they occur.

By using GMS3, we "visualize" underground risks that cannot be detected by the naked eye, supporting the safe and secure maintenance of road infrastructure.

Using a multi-channel antenna to send and receive electromagnetic waves, it can detect cavities, anomaly signals, and buried objects up to about 2 meters underground in 3D, similar to a CT scan. Compared to conventional technology, this allows for broad-area surveys to be completed in a shorter time, achieving efficient and high-precision diagnostics.

By combining panoramic cameras and location information, it enables 3D mobile measurements with 1/500 accuracy as defined by public surveying standards. This allows accurate and efficient acquisition of above-ground data while driving, reducing the burden of on-site work and speeding up surveys.

Data obtained via ground penetrating radar and the mobile mapping system are completely synchronized using GPS timestamps. This allows for integrated management of 3D data above and below ground, enabling the construction of highly accurate 3D databases. It also allows for smooth integration with dedicated viewer software and various GIS tools.